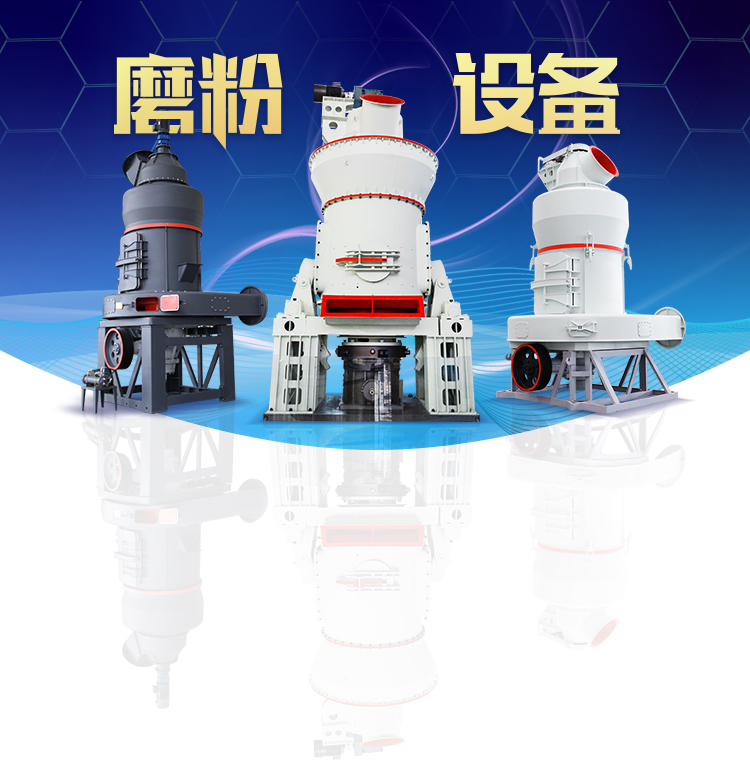

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Silicalite Cement Additive

.jpg)

Nanomicron soda residue as green nucleation seeding additive

2024年3月15日 It is proved that it is possible to utilize SR as an accelerating additive for silicate cement The 12hour early compressive strength of silicate cement mortar was increased by 2023年12月18日 The CSH–PCE additive provides more nucleation area for cement to hydrate more quickly Al 3+ has been proven to enter the CSH structure and influence the composition Preparation and properties of calcium aluminum silicate 2024年7月25日 One system currently being investigated is MgOSiO 2 based binders, which consist of reactive magnesia cement (RMC) and a silica source [22–25] These binders Development of 3Dprinted magnesium silicate hydrate cement The nature of the synthetic calcium silicates additives’ effect obtained by the method of sucrosemodified calcium hydro silicates thermolysis on the technological properties of the cementEffect of Calcium Synthetic Hydro Silicate Additives on the Cement

.jpg)

Unlocking the potential of ordinary Portland cement with

2024年1月3日 Here we show a hydration control additive that selectively modifies the hydration kinetics, thereby facilitating enhanced dissolution of aluminates (calcium aluminoferrite and 2022年7月1日 Colloidal silica was used to increase the resistance of readymixed concrete to deicing salts and brines during the winter season The nanoenhanced concrete (NEC) needed to be easy to batch and place as Employing a Colloidal Silica Admixture in Ready 2024年1月4日 In this paper, we present our Hydration Control additive (HyCon® B) which fundamentally alters the hydration process by shifting the main reactions of C4AF and C3A Unlocking the potential of ordinary Portland cement 2022年1月4日 Calcium silicate hydrate (C–S–H) gel is the glue of Portland cement that governs most of the physicochemical properties of concrete Inherently, understanding and controlling its complex gel structure has long A century of research on calcium silicate hydrate

A molecular dynamics study of calcium silicate hydrates

2021年1月28日 本研究利用分子动力学模拟探讨了常用的集料相碳酸钙/二氧化硅与水化硅酸钙 (CSH)之间的界面相互作用机制, 以及湿度对界面性质的影响。 结果表明, 无论在干或湿条件 6 天之前 IsoGuard cement additive is a dryblended material that can be efficiently added and blended into the cement design, eliminating the additional equipment and requirements that liquid additives demand When utilized at the optimum concentration, the IsoGuard cement additive provides many of the same benefits of a liquid latex additive and can be IsoGuard™ enhanced cement slurry additive solution2022年7月10日 The additive percentages included in the concrete have been based on preliminary investigations of chemical additives for concrete , where a range of 06 to 3% is taken for the waterreducing additives with respect to the weight of the cement This serves for the study in order to obtain the percentages 05, 1, 2, 3 and 4 for the silica gelDetermination of the Influence of an Absorbing Silica Gel in Concrete • The greater the percentage of Halliburton gel used, the greater the water requirement and the lighter the slurry weight • Actual slurry and set volume of cement is increased, resulting in an appreciable reduction in fillup cost Silicalite™ Additive • Imparts an early pozzolanictype reaction that extends lightweight cementHaliburton Cement Additive

Employing a Colloidal Silica Admixture in ReadyMixed Concrete

2022年7月1日 33 Abrasion Resistance The abrasion resistance of the specimens was tested after 56 (Figure 3a) and 90days (Figure 3b) in the freezethaw and deicing brine environment, in accordance with ASTM C779/C779M, Procedure CAt both 56 and 90days the concrete mixture with the colloidal silica (NEC) exhibited a greater resistance to the induced abrasive wear3 天之前 MR21 and MR 12 are cement retarders used in medium temperature ranges for oilfield cementing operations, whereas MR21L is the liquid version of MR 21 cement retarder MR32 is a high temperature retarder used in bottom hole circulating temperatures up to 350 °F (1766 °C), whereas MR32L is the liquid version of this cement retarder MR5 designed to use when the Microsilica products for oil well cementing Elkem2023年12月18日 The CSH–PCE additive provides more nucleation area for cement to hydrate more quickly Al 3+ has been proven to enter the CSH structure and influence the composition and morphology In this paper, CASH–PCE nanocomposites (CPNs) with different Al/Si ratios are synthesized at different PCE concentrations using a coprecipitation methodPreparation and properties of calcium aluminum silicate 2019年4月30日 This study systematically investigated the additive amount of sodium silicate, and curing temperature on the setting time of cement paste before and after the addition of AMPSIA; furthermore, the mechanisms of sodium silicate in prolonging the setting time of cement paste were elaborated basing on the result obtained by Xray diffraction (XRD), BET nitrogen Delaying the hydration of Portland cement by sodium

.jpg)

Acceleration and Retardation of Portland Cement

cent In all cases percentages are given on the cement weight basis As a further variable, the additive was either dissolved in the entire mixing water and added to the cement at the start, or the bulk of the water was added at the start and the additive, dissolved in the rest of the water, was added after 2, 4, or 8 minutes This sort of2007年2月5日 What is claimed is: 1 A method of cementing comprising: introducing a cement composition into a well bore having a bottom hole circulating temperature of at least about 500° F, the cement composition comprising: water; a cement; and a fluid loss control additive comprising a graft polymer, the graft polymer comprising: a backbone comprising a lignite; a Method of using lignite grafted fluid loss control additives in 2023年12月7日 It is acknowledged [] that the incorporation of mineral fillers in concrete mixtures stands as a priority for reducing cement consumption and enhancing both its technological and operational propertiesNatural additives encompass crushed volcanic and sedimentary rocks, diatomites, volcanic ash, and tuff Within technogenic additives lie waste or byproducts from Analysis of Experience in the Use of Micro and 2023年12月1日 Cement additives play a crucial role in enhancing various aspects of cement performance, including strength, durability, workability, and setting time The paper provides an indepth analysis of Advancements in Cement Technology: A

Cement Agents Lightweight Cement,Agents,Lightweight

Silicalite™ Cement Additive with 5050 Pozmix® Cement Used to decrease slurry weight, increase slurry volume, minimize free water, and prevent compressive strength retrogression up to 300°F (1489°C) Spherelite® Cement Additive 2024年11月24日 How It Works: Sikacrete®950 DP is a pozzolanic material that consists primarily of fine silicon dioxide particles in a noncrystalline formSilica fume particles have a diameter of less than 1μm; about 100 times smaller than the average cement particle Pozzolanic action: A chemical reaction takes place between the free lime Ca (OH) 2 in the cement paste Sikacrete®950 DP Silica Fume2024年8月7日 haliburton cement additive Free download as PDF File (pdf), Text File (txt) or read online for freeHaliburton Cement Additive PDF Scribd2011年1月13日 582 M P S Chandrawat et al: Impact of Sodium Silicate parametric study has been conducted to investigate the influence of the molar ratio of MgO/MgCl2 and H2O/MgCl2 on the properties of (MOC) magnesium oxychloride cement 16 The chemical composition of the additive available amply in commercial grade is Na2SiO3 x H2OThe literature is silent about IMPACT OF SODIUM SILICATE AS AN ADDITIVE ON THE

.jpg)

(PDF) Robust layer interface in cement additive

2022年1月4日 Weak layer interface is a nonnegligible issue in the domain of cement additive manufacturing, which results in lacking integrity, mechanical inferiority and deteriorated durability In order to Study Main Halliburton Additives flashcards from Brian Dorfman's Georgetown University class online, or in Brainscape's iPhone or Android app Learn faster with spaced repetition Silicalite DEcrease the density of slurry 30 Q Heavy Weight additives A BArite sand High Dense 31 Q Heavy Weight Additive for Mud and Cement 85 lb added Main Halliburton Additives Flashcards by Brian DorfmanWhat is claimed is: 1 A method of cementing comprising: introducing a cement composition into a well bore having a bottom hole circulating temperature of at least about 500° F, the cement composition comprising: water; a cement; and a fluid loss control additive comprising a graft polymer, the graft polymer comprising: a backbone comprising a lignite; a first grafted Method of using lignite grafted fluid loss control additives in Effect of sodium silicate on Portland cement/calcium aluminate cement/gypsum richwater system: strength and microstructure Zhiming Wang ab, Yuning Sun * ab, Shuo Zhang a and Yonglong Wang a a School of Energy Science and Engineering, Henan Polytechnic University, Jiaozuo, , China Email: sunyn639@126 b State and Local Joint Engineering Effect of sodium silicate on Portland cement/calcium aluminate cement

Concrete Additives Types, Benefits, and Applications

2024年8月25日 Benefits of Using Concrete Additives Incorporating additives into concrete mixes offers several key benefits, including: Improved Durability: Additives enhance the resistance of concrete to environmental factors such as freezethaw cycles, chemical attack, and corrosion, extending the lifespan of structures Enhanced Strength: Certain additives, such as silica SILRES ® BS silicone additives improve the properties and storage stability of cement in the long term Usually added during the cement production process, highperformance SILRES ® BS organosilicone additives are very effective in Cement Admixtures and Cement AdditivesBuilding Decorative Cement In Building Decorative Materials, 2011 521 Colored Cement Colored silicate cement, shortened as colored cement, is a kind of hydraulic cementing material made in these two ways: mix white silicate cement clinker, super white gypsum, mineral pigment and additives (water proofing agent, water retaining agent and plasticizer etc) together and Silicate Cement an overview ScienceDirect Topics2017年7月23日 Ch4 Cementing Additives Free download as PDF File (pdf), Text File (txt) or read online for free The document discusses various cement additives used in high pressure and high temperature cementing operations It Ch4 Cementing Additives PDF Cement Gases

.jpg)

US Patent for Cement composition for lost circulation

SA1015™ is a cement additive which acts as a suspending agent, available from Halliburton Energy Services, Inc, Houston, Tex Silicalite™ cement additive is made from a finely divided, high surfacearea silica, available from Halliburton Energy Services, Inc, Houston, Tex, and may impart thixotropy to some cement slurries2021年1月1日 High additive levels have been necessary to produce desirable cement slurry properties because ofextreme temperatures encountered in south Texas deepwell cementing, andinterference with chemical Cement additives ResearchGateDensityreducing additives comprising lowdensity particulates, and cement compositions comprising such additives, are provided In one embodiment, the present invention provides a cement composition comprising: a cement component; a densityreducing additive comprising particulates that comprise an agglomerating material; and a base fluidLowdensity cement compositions, densityreducing additives, and 2024年3月6日 Understanding Concrete Additives Concrete additives, also referred to as admixtures are substances incorporated into the mixture to improve or alter its characteristics to suit construction requirements Their main objective is to enhance the performance of concrete across stages of construction from mixing to the solidified formBoosting Strength and Durability with Concrete Additives

Types of Admixtures Additives for Concrete DIY Doctor

Additives, or admixtures should on the whole only be used when a given situation requires them but there are some that can be used to enhance a general concrete mix For a full rundown on the different types of concrete additives and admixtures and how they should be used, read on below Using Admixtures and Additives in Concrete and Mortar Mixes2024年9月26日 Cement additives, which are more commonly known as cement grinding aids (CGAs) are chemicals that are added to the cement mill to improve both the efficiency of the grinding process and the quality of the produced cement These additives can significantly enhance the productivity of cement mills, reduce energy consumption, and improve the Advice about cement additives World CementTwo important factors in this strategy are the optimization of the adhesion between the additive and the cement particles and the homogeneous dispersion of the additive within the cement As an example of this approach, Wang et al combined carbon nanotubes (CNTs) or biomineralized CNTs with a calcium phosphate cement, increasing the Calcium Silicate Cement an overview ScienceDirect Topics6 天之前 IsoGuard cement additive is a dryblended material that can be efficiently added and blended into the cement design, eliminating the additional equipment and requirements that liquid additives demand When utilized at the optimum concentration, the IsoGuard cement additive provides many of the same benefits of a liquid latex additive and can be IsoGuard™ enhanced cement slurry additive solution

Determination of the Influence of an Absorbing Silica Gel in Concrete

2022年7月10日 The additive percentages included in the concrete have been based on preliminary investigations of chemical additives for concrete , where a range of 06 to 3% is taken for the waterreducing additives with respect to the weight of the cement This serves for the study in order to obtain the percentages 05, 1, 2, 3 and 4 for the silica gel• The greater the percentage of Halliburton gel used, the greater the water requirement and the lighter the slurry weight • Actual slurry and set volume of cement is increased, resulting in an appreciable reduction in fillup cost Silicalite™ Additive • Imparts an early pozzolanictype reaction that extends lightweight cementHaliburton Cement Additive 2022年7月1日 33 Abrasion Resistance The abrasion resistance of the specimens was tested after 56 (Figure 3a) and 90days (Figure 3b) in the freezethaw and deicing brine environment, in accordance with ASTM C779/C779M, Procedure CAt both 56 and 90days the concrete mixture with the colloidal silica (NEC) exhibited a greater resistance to the induced abrasive wearEmploying a Colloidal Silica Admixture in ReadyMixed Concrete 3 天之前 MR21 and MR 12 are cement retarders used in medium temperature ranges for oilfield cementing operations, whereas MR21L is the liquid version of MR 21 cement retarder MR32 is a high temperature retarder used in bottom hole circulating temperatures up to 350 °F (1766 °C), whereas MR32L is the liquid version of this cement retarder MR5 designed to use when the Microsilica products for oil well cementing Elkem

.jpg)

Preparation and properties of calcium aluminum silicate

2023年12月18日 The CSH–PCE additive provides more nucleation area for cement to hydrate more quickly Al 3+ has been proven to enter the CSH structure and influence the composition and morphology In this paper, CASH–PCE nanocomposites (CPNs) with different Al/Si ratios are synthesized at different PCE concentrations using a coprecipitation method2019年4月30日 This study systematically investigated the additive amount of sodium silicate, and curing temperature on the setting time of cement paste before and after the addition of AMPSIA; furthermore, the mechanisms of sodium silicate in prolonging the setting time of cement paste were elaborated basing on the result obtained by Xray diffraction (XRD), BET nitrogen Delaying the hydration of Portland cement by sodium cent In all cases percentages are given on the cement weight basis As a further variable, the additive was either dissolved in the entire mixing water and added to the cement at the start, or the bulk of the water was added at the start and the additive, dissolved in the rest of the water, was added after 2, 4, or 8 minutes This sort ofAcceleration and Retardation of Portland Cement 2007年2月5日 What is claimed is: 1 A method of cementing comprising: introducing a cement composition into a well bore having a bottom hole circulating temperature of at least about 500° F, the cement composition comprising: water; a cement; and a fluid loss control additive comprising a graft polymer, the graft polymer comprising: a backbone comprising a lignite; a Method of using lignite grafted fluid loss control additives in

Analysis of Experience in the Use of Micro and

2023年12月7日 It is acknowledged [] that the incorporation of mineral fillers in concrete mixtures stands as a priority for reducing cement consumption and enhancing both its technological and operational propertiesNatural additives encompass crushed volcanic and sedimentary rocks, diatomites, volcanic ash, and tuff Within technogenic additives lie waste or byproducts from

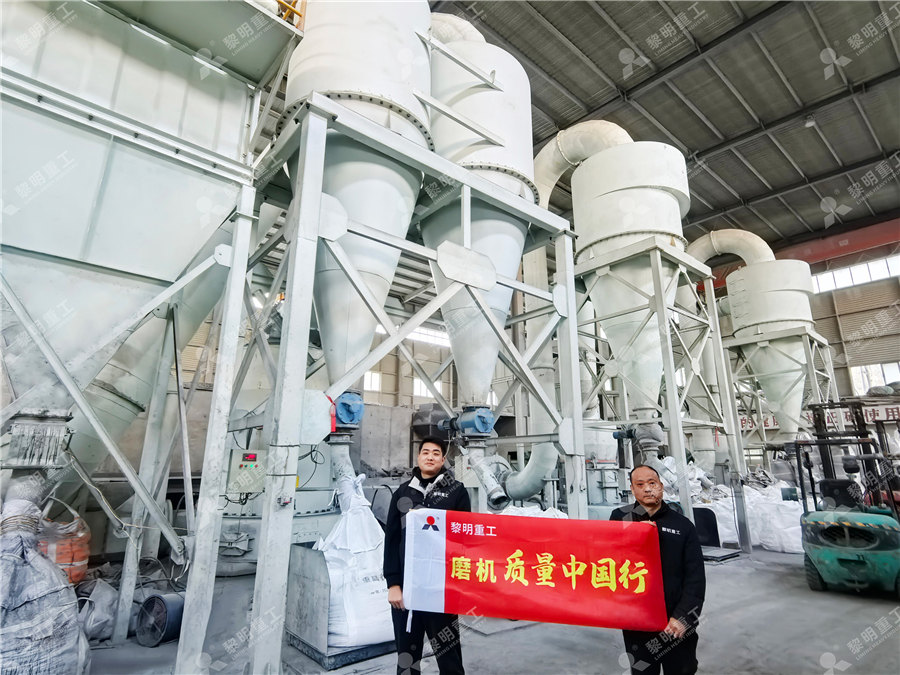

秦皇岛大型制造企业

--氧化铁加工机械

--活性炭磨粉设备客户现场

--裂解炭黑雷蒙磨流程图

--椰壳活性炭磨粉机石头磨粉机抛光视频

--湖北宜昌重钙方解石磨粉机

--南宁市重型机械集团地图

--叶腊石T型磨粉机

--1820粉碎机的使用与维护

--粉碎铝钒土用方解石磨粉机

--立磨的细度

--小型制粉厂买个污泥处理需投资多少

--40TPH悬辊重钙粉研磨机

--安徽重质碳酸钙环辊磨全套设备价格

--pf1622预粉磨砂粉立磨精品砂粉设备

--80TPH欧版方解石磨粉机

--950x1200重钙矿石安装尺寸

--碾磨机衍磨研磨

--云阳硅粉加工

--宣化小型立磨

--花岗岩碳酸钙加工设备氟石膏

--石英重钙微粉磨

--贵阳轻质砖生产厂贵阳轻质砖生产厂贵阳轻质砖生产厂

--磨机重钙磨粉机雷蒙机高细立磨氧化钙研磨机

--4R3216磨粉机

--特雷克斯立式辊磨机

--打精品砂粉设备的产家

--北京微粉辊磨机

--粉煤灰粉磨没备

--四川大理石欧版磨制造商

--